NW Best Machine Shop is a Lean Manufacturing shop where it’s workplace follows the 5S organizational and housekeeping methodology.

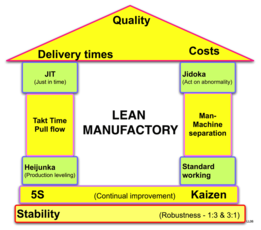

Lean manufacturing or lean production, often simply “lean”, is a systematic method for the elimination of waste (“Muda”) within a manufacturing system. Lean also takes into account waste created through overburden (“Muri”) and waste created through unevenness in work loads (“Mura”). Working from the perspective of the client who consumes a product or service, “value” is any action or process that a customer would be willing to pay for.

Essentially, lean is centered on making obvious what adds value by reducing everything else. Lean manufacturing is a management philosophy derived mostly from the Toyota Production System (TPS) (hence the term Toyotism is also prevalent) and identified as “lean” only in the 1990s.[1][2] TPS is renowned for its focus on reduction of the original Toyota seven wastes to improve overall customer value, but there are varying perspectives on how this is best achieved. The steady growth of Toyota, from a small company to the world’s largest automaker,[3] has focused attention on how it has achieved this success.

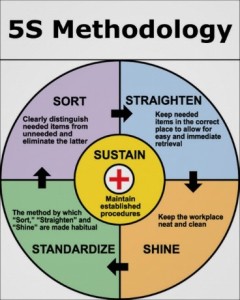

5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results. The term refers to five steps – sort, set in order, shine, standardize, and sustain – that are also sometimes known as the 5 pillars of a visual workplace. 5S programs are implemented by teams working together to get materials closer to operations, right at workers’ fingertips and organized and labeled to facilitate operations with the smallest amount of wasted time and materials.

The 5S system is a good starting point for all improvement efforts aiming to drive out waste from the manufacturing process, and ultimately improve a company’s bottom line by improving products and services, and lowering costs.

“A place for everything, and everything in its place” is the mantra of the 5S method and the result is an improved manufacturing process and the lowest overall cost for goods produced.

5S was developed in Japan and stands for the Japanese words seiri (tidiness), seiton (orderliness), seiso (cleanliness), seiketsu (standardization), and shitsuke (discipline). These words have been adopted to English to maintain “5S.”